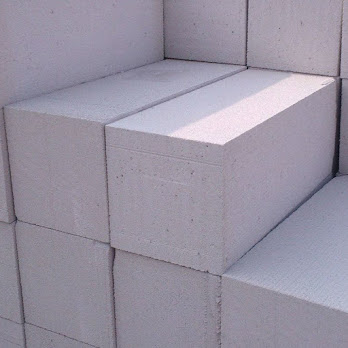

Autoclaved aerated concrete (AAC block)

Autoclaved aerated concrete blocks are another type of modern masonry units formed of a mix of lime, sand(along with fly ash), cement, and admixture ( generally aluminum paste). As the name itself explains, these blocks act kind of concrete blocks that are made with micro air-entrained inside it. Thus such blocks are very light weighted. The aluminum paste added to the mix made such bricks more lightweight, finely microporous, and high insulation. The quartz from sand and calcium hydroxide from cement and lime in mix form calcium silicate hydrates which are responsible for its strength.

The aluminum powder also reacts with calcium hydroxide to form hydrogen gas, which is mainly responsible to create microspores giving cellular structure to concrete. The brick along with a comparison of its equivalent density of other masonry units seems to have high compressive strength. But the strength alone of brick is not suitable to use it as a structural construction material.

Fly ash brick

Fly ash brick is masonry units of building construction, which is made up of fly ash, sand, cement, and gypsum (or sometimes directly Ordinary Portland cement) along with proper mix with water. The fly ash is generally the remnants of the burnt coals along with different gases fumes like Sulphur, carbon, mercury, produced generally from thermal plants.

The fly ash dust contains harmful chemical compounds byproduct which if left in the environment without proper disposal then can affect the environment, atmosphere, and ecology of the surrounding.

AAC blocks vs Fly ash bricks

|

Sl No. |

Parameters |

AAC BLOCKS |

FLY ASH BRICKS |

|

1 |

Major component |

In Acc blocks , aluminum acts as major component factor. |

Fly ash bricks use the fly ash as major raw material. |

|

2 |

Percentage composition |

Lime – 10%-15% Sand (often with fly |

Fly ash – 50%-80% Sand – 20%-40% Cement – 5%-30% Gypsm – 2% -5% |

|

3 |

Specific gravity and density |

Density – 1700kg/m³-1850 kg/m³ |

Density – 550kg/m³- 650 kg/m³ Sp. Gravity – 0.6- .65 |

|

4 |

Size (mm) |

600x200x75/300 (market size nearly equal as suggested from IS

2185 part 3) |

190x90x90(modular) 230x110x70/30 (non modular) ) (market size

nearly equal as suggested from IS 13757) |

|

5 |

Sound resistance |

45dB – 200 dB (depends on thickness) |

40 dB |

|

6 |

Dead load reduction (comparision to concrete) |

Upto 80% |

30% -35% |

|

7 |

Compressive Strength |

4 N/mm²- 8 N/mm² |

7N/mm² -10 N/mm² |

|

8 |

Thermal conductivity |

Very good insulation. Which is about 0.16 to 0.18 W/Mk |

Not good insulating units. Which is about 0.9 to 1.05 Watt/m² °C |

|

9 |

Efflorescence |

Comparatively high as it contains more amount of lime |

Comparatively less as it is cured more and contains less lime

content |

|

10 |

Water Absorption |

Relatively high due to capillary suction |

15%-20% |

Thank you...........😍😍😍

0 Comments